Interview with Roger Berntsen, CEO and co-founder of AnyPlan3D

In an increasingly digitalized market, the oil and gas exploration and production (E&P) industry is facing a significant challenge in how it effectively and efficiently makes use of the massive array of data it has and owns. While other industries have advanced in their digital transformation, the upstream sector continues to work in a similar manner as it operated over 10 years ago, needing to catch up.

In line with our Energy Pulse analyses, we bring you another newsletter featuring the key takeaways from our conversation with Roger Berntsen, from AnyPlan3D, a leading company in developing solutions for synchronized activity management to improve operational and financial performance, and in the last several years with a focus on the Upstream industry (E&P – exploration and production of oil). In this context, AnyPlan3D has developed innovative solutions that aim to optimize business decisions (Better and Faster) and thereby enhance financial performance through data integration and activity synchronization. In this interview, we delve into the details of AnyPlan3D’s approach and its impact on the exploration and production performance? (market), focusing on the specific needs of E&P companies and the demand they represent in terms of them improving performance.

Roger Berntsen

CEO and co-founder of AnyPlan3D

What is AnyPlan3D?

In response to the challenge faced by the Upstream industry in its digitalization process, AnyPlan3D has developed innovative solutions to address this vital need. The company has realized that many energy sector companies are investing significant resources in systems that generate a large amount of data, but much of this data ends up not being used or being used ineffectively and inefficiently.

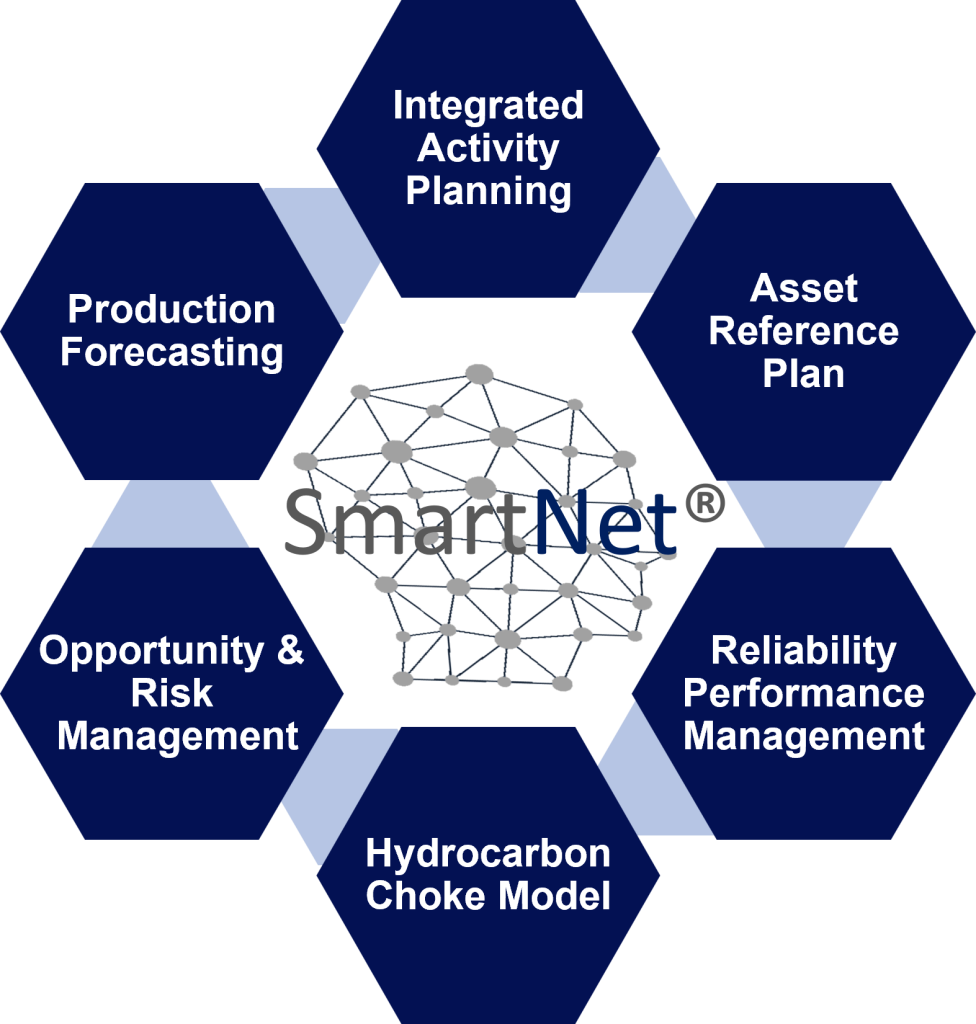

In view of this situation, AnyPlan3D has focused its efforts on identifying the relevant data for business performance, particularly as measured in financial terms. Their objective is to interconnect all relevant systems and gather the pertinent data to improve the decision basis and financial performance of companies. To achieve this, they have developed a synchronization network called SmartNet, which acts as a virtual factory for the Upstream industry. By virtual factory we mean a “smart” data warehouse or lake that utilizes data in its original location, and can therefore apply dynamic analyses of the data, rather than analyses based on static data warehouses.

SmartNet allows for interconnecting and synchronizing all relevant activities within the oil industry, making visible to all levels of decision makers what needs to be done to ensure each activity is scheduled at the appropriate time to minimize activity conflict and for relevant levels of management to intervene in a timely manner. This is crucial to avoid wasting resources or avoid unexpected consequences. Through optimization and rescheduling, conflicts between activities are effectively resolved.

Image 1: The foundational operational processes integrated by AnyPlan3D’s Smart Net.

AnyPlan3D has successfully implemented this approach in collaboration with National Oilwell Varco, involving 200 companies and managing terabytes of synchronized data. Users can interact with SmartNet, make decisions, and publish their plans on the network, while maintaining ownership of their data. This allows for real-time interactive work and avoids the latency that could be present in other data storage approaches.

Additionally, AnyPlan3D uses 3D models for visualization and support of exploration and production industry activities. These digital models represent elements connected to activities in the network and can be utilized to optimize support routes, among other applications.

Integrated Optimization for the Upstream Oil and Gas Industry: The Comprehensive Solution of Anyplan3D

The main business areas applicable to Anyplan3D extend beyond the oil and gas industry, including infrastructure, aviation, and the entire energy sector. However, in the specific case of the upstream oil and gas sector, Anyplan3D focuses on optimizing production with maximum benefit and minimal environmental impact. It offers various planning capabilities in domains such as safety, drilling, helicopter scheduling, personnel on board (POB) operations, supply chain, project planning, and maintenance, adapting to the needs of each company. Anyplan3D makes use of the data that already exist within a company´s various planning systems, by connecting and synchronizing the data from this variety of data sources.

Anyplan3D can be integrated with almost all other technologies and digital systems commonly used in the oil and gas industry, e.g. drilling automation, SAP automation and data, production monitoring and planning including management. Integration can be achieved through services to transfer data between Anyplan3D and other systems in real-time or on a scheduled basis. Anyplan3D can receive raw data and convert it into objects within its network model, allowing data to be effectively connected and utilized in integrated planning.

The integrated planning of Anyplan3D helps upstream oil and gas companies optimize their operations and improve profitability by synchronizing activities and minimizing resource waste. By using SmartNet, Anyplan3D achieves alignment and synchronization of activities, avoiding unnecessary delays. This allows for efficient use of resources and a balanced production flow to achieve target objectives. Anyplan3D offers a unique solution in the upstream industry as it can build customized production lines and synchronize all activities related to maintenance, operations, drilling, and more. Its ability to manage workflow comprehensively and synchronized provides a significant competitive advantage in the pursuit of optimization and improved cost management and profitability for upstream companies.

The Importance of Partnerships in the Transformation of the Oil and Gas Industry

Anyplan3D fully acknowledges the complexity involved in implementing its solution and understands the importance of having expertise to thoroughly comprehend the systems, organization, and market challenges of its clients. For this reason, a strategic collaboration agreement has been established where NTTData actively participates in the implementation of the solution, providing expertise that ensures smooth integration of clients’ systems with Anyplan3D. Additionally, AnyPlan3D plays a key role in the training and change management phase to ensure that users adapt and make the most of the digital adoption tools provided by NTTData. The ultimate goal is to offer an end-to-end solution that fully satisfies the training needs of Operator´s personnel, utilizing tools like MELT (NTT Data’s e-learning platform).

The future of Oil & Gas and next Gen of E&P

In the oil and gas industry, significant investment has been made in digital transformation, resulting in a vast amount of data generation. However, many companies are not yet advancing to the next stage and need experts to help determine which data is relevant and where to focus. Despite having technologies like IoT and consultants offering AI and digital twin solutions, management is puzzled about effectively utilizing all this data for valuable business insights.

AnyPlan3D has a clear vision and with foresight they are incorporating and adapting its solutions to new technologies such as Artificial Intelligence (AI). With 35 years of AI experience, including research programs with prominent Upstream Operators like Equinor and collaboration with leading research institutions, AnyPlan3D aims to offer cutting-edge solutions to boost efficiency and productivity in operations, maintaining a strong focus on data security, reliability, and accuracy.

It is critical for the Upstream industry to utilize the wealth of data it possesses and transform it into information that will help decision makers improve financial and operational performance; and also seek software solutions that can more easily make use of data the industry already own or has access to. Traditional approaches like data lakes or purpose built data warehouses are both expensive to create and maintain, do not provide the dynamic data in a timely manner nor do they significantly contribute to the end result of improved performance. They do however provide an opportunity and market for expensive consultants´ advice with little accountability for outcome. Adopting a distributed responsibility model where original data owners remain in charge until delivery to clients is essential. Data integration under this approach enables precise decision-making and total control over data quality and ownership.

For future companies, finding a solution provider that offers information management based on mesh principles will be key to maximizing data generated in the upstream industry.

In conclusion, through an insightful conversation with Roger Berntsen from Anyplan3D, we explored the advantages and opportunities in the field of integrated planning for upstream oil and gas companies. Berntsen emphasizes the need to effectively leverage industry-generated data and turn it into valuable business insights. He highlights Anyplan3D’s unique approach, based on distributed data ownership and responsibility, allowing companies to retain control and data quality while efficiently interconnecting them. The article emphasizes the crucial role of integrated planning in optimizing operations and improving profitability in the upstream industry. Therefore, the future of the oil and gas industry depends on companies’ ability to intelligently use the data generated and find solutions or partnerships like Anyplan3D.